Smart Home Programming The Beginner’s Guide

What is Smart Home Programming?

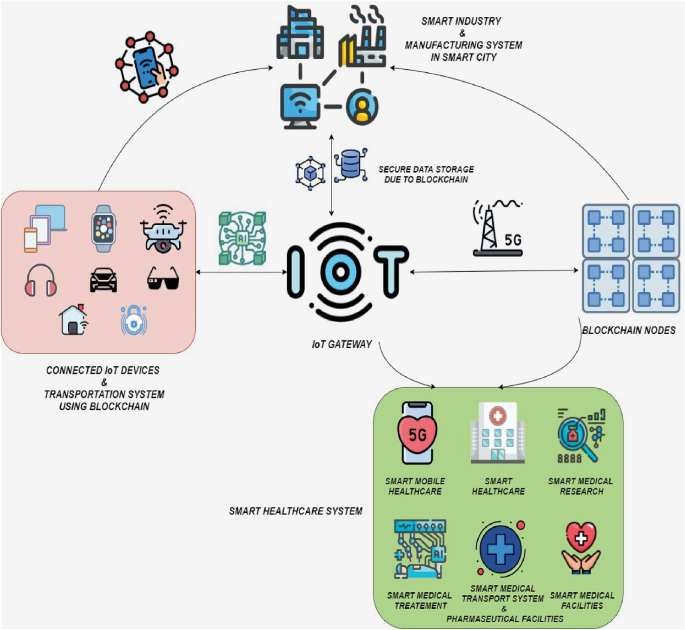

Smart home programming is essentially the process of writing code to control and automate various devices and systems within your home. This could range from simple tasks like turning lights on and off at specific times to more complex scenarios like adjusting your thermostat based on occupancy and weather conditions. It involves interacting with various smart home platforms and APIs (Application Programming Interfaces), which are essentially sets of rules and standards that allow different devices and software to communicate with each other.

Choosing Your Smart Home Platform

The first step is deciding which smart home ecosystem you’ll work with. Popular options include Home Assistant (open-source and highly customizable), SmartThings (from Samsung), and HomeKit (from Apple). Each platform has its strengths and weaknesses. Home Assistant offers maximum flexibility but requires more technical knowledge. SmartThings and HomeKit are more user-friendly but offer less control. Consider factors like the devices you already own, your programming experience, and the level of customization you desire when making your choice.

Understanding APIs and Integrations

Most smart home automation relies on APIs. Think of an API as a translator between different devices and your program. For instance, if you want to control your Philips Hue lights through Home Assistant, Home Assistant needs to communicate with the Philips Hue API. This involves learning how to send commands (e.g., “turn light on,” “set color to blue”) in the specific format required by the API. Many platforms simplify this process, but understanding the basic concept is crucial.

Basic Programming Concepts for Smart Home Automation

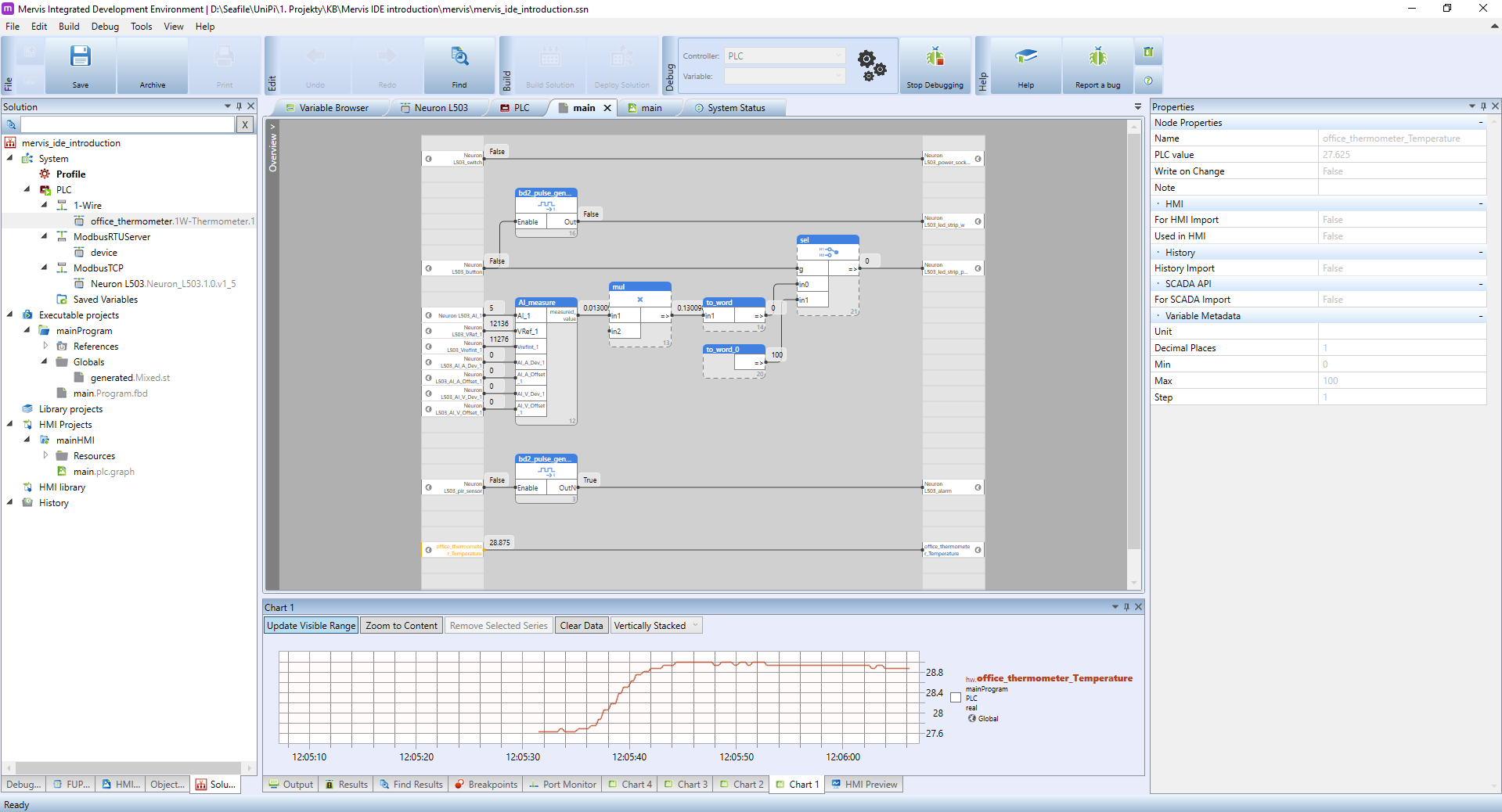

While you don’t need to be a professional programmer to get started, familiarity with basic programming concepts will greatly benefit you. These concepts often include variables (to store information like temperature or light level), conditional statements (like “if the temperature is below 70, turn on the heating”), loops (to repeat actions), and functions (to organize your code into reusable blocks). Many platforms offer simplified programming interfaces or utilize visual programming tools that minimize the need for complex coding.

Getting Started with a Simple Project: Automated Lighting

A good starting point for beginners is automating your lights. This could involve setting up a schedule to turn lights on at sunset and off at sunrise. This simple project allows you to practice interacting with the API of your chosen lighting system (like Philips Hue, LIFX, or similar) and implement basic scheduling capabilities. Many platforms provide clear instructions and sample code for such projects.

Working with Sensors and Environmental Data

Adding sensors to your smart home opens up a world of automation possibilities. Motion sensors can trigger lights to turn on when someone enters a room, temperature sensors can control your thermostat, and door/window sensors can activate security alerts. Integrating sensors involves understanding how to read data from these devices and use that data to trigger actions in your program. You’ll need to learn how to interface with your chosen sensor’s API or protocol.

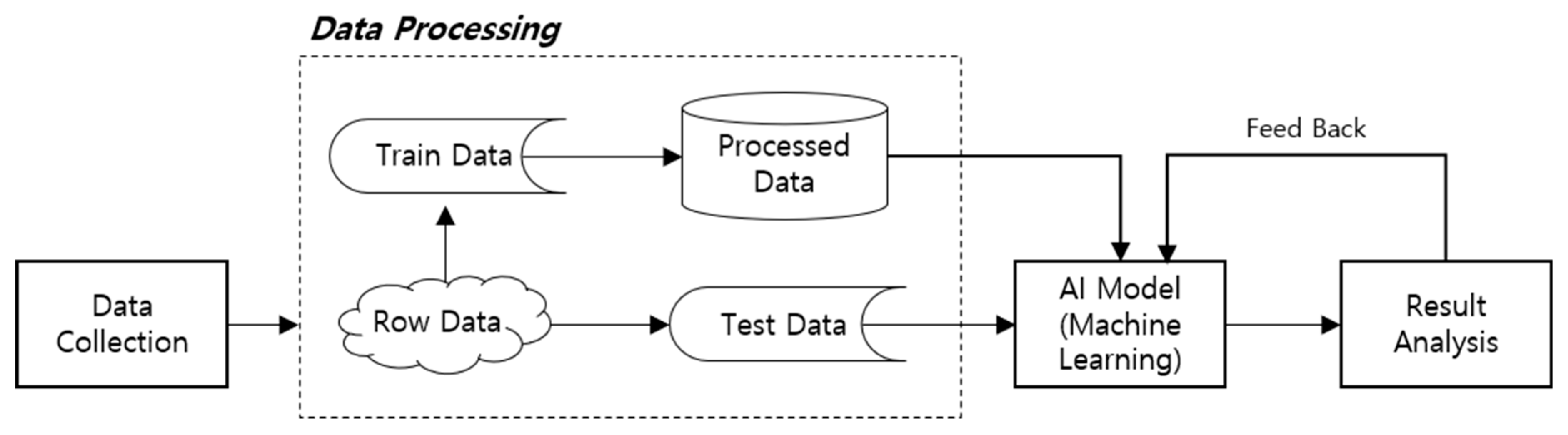

Advanced Smart Home Programming: Machine Learning and AI

Once you’ve